As a professional and strong energy meter factory, having the ability to research and produce electricity meters is not enough. With the advancement of technology, energy meter factory must possess extensive skills combined with software and hardware systematic comprehensive capabilities. Faccurate measurementse, AMI prepaid metering solutions require a sufficient understanding of AMI applicatio , as well as involvement in powermeasurementst, data collection, data analysis, archive management, and electricity sales management. In terms of research and development, it requires a team of hardware engineers, structural engineers, embedded software engineers, system software engineers, and experienced product managers.

I will briefly explain the module composition of an intelligent prepaid metering solutions.

1. Measurement Module: Adopts professional measurement chips with a high accuracy grade, capable of measuring various data types and achieving bidirectional measurements.

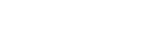

2. Data Acquisition: The main focus is on the communication capabilities of the electricity meter and the system platform's communication connection, as well as data acquisition stability. There are mainly two forms of communication: one is the combination of a local area network and a wide area network, where an electricity meter is connected to a central controller through RS485, PLC, LoRa, WiFi, Zigbee, etc. And then, the central controller transmits the data to the system platform via GPRS, Ethernet, and other methods.

3. Data Analysis: Summarize and analyze the collected data to form electricity usage patterns and power quality data. This provides guidance on how to make the power supply and power grid more rational, efficient, and of higher quality.

4. Safe Electricity Usage: The electricity meter has load control functions such as power control, time control, and remote control. The control plans mentioned above require a system platform for creating and implementing them based on data management, which is then communicated to the electricity meter. It also has a prepaid function that automatically cuts off the power supply when there is a debt, thus solving the problem of difficult fee collection.

5. Fault Diagnosis and Prediction: Utilize measurement technology and data analysis methods to identify and diagnose system faults, as well as forecast potential future issues.

6. Mobile payment: This prepaid measurement solution uses STS non-medium recharge, combined with online payment, to realize user-initiated mobile payment for electricity purchase. It improves convenience and reduces electricity operation costs without the need for sales outlets.

7. Archive Management: Manage users' archives and form data related to electricity purchases and usage.

The application of prepaid metering solutions involves the installation and management of measurement systems, which require personnel with a certain level of expertise to handle. The installation and management of measurement systems needs to be designed and planned in advance to meet the configuration requirements of the venue equipment, ensuring the stable operation of the entire system. Standard requirements and guidance for the installation and management of measurement systems should be established to clarify the work requirements. Clear instructions are needed for regular maintenance, data security backup, timely updates of antivirus software, and system platform inspections. The personnel responsible for the installation and management of measurement systems need to undergo systematic training and pass the examination before they can be certified to go on duty.

The prepaid metering solutions by energy meter factory can help us understand and control the performance, quality, energy usage, and safety of systems, thereby improving system efficiency and reliability. In the construction and long-term operation of the entire solution, it is necessary to have clear and rigorous installation and management specifications for the measurement system, as well as professional personnel configuration, to ensure the accurate, reliable, and safe long-term operation of the system.

英语

英语 中文简体

中文简体